Tests show that standard cone bearings have less friction than sealed ball bearings

Traditional cup and cone bearings were compared with cartridge bearings with and without seals. Two types of lubricant were also compared. For each bearing configuration, measurements of the frictional drag torque were made for different types of bearings with loads varying between zero and 264 N and rotational speeds up to 600 rpm. For a typical road racing bike, this would correspond to a speed of 48 mph.

Test method

A shaft was driven by an electric motor. The shaft passed through large pillow block bearings supporting the assembly. A bicycle hub was mounted between the pillow block bearings with the shaft replacing the axle. At each end of the hub, a plate was attached. On either side of the hub, running parallel to the shaft, knife edges connected the plates to each other. Load weights were suspended between the knife edges. This arrangement allowed the load weights to apply a vertical force to the bearings while remaining balanced so as not to offer any moment resisting rotation of the hub. An additional test weight was suspended from the plates directly below the center of the bicycle hub. When the shaft is rotated, friction causes the hub to rotate. This rotation moves the test weight out of alignment with the shaft so that it produces a restoring moment. At equilibrium, the frictional moment is equal to the restoring moment and from the angle of the hub, the friction can be calculated.

To minimize the effects of inertia and friction within the knife-edge, the hub was disturbed so that it rocked. Measurements were taken after the resulting oscillations had damped out, as well as in both directions. These measurements were averaged.

Cartridge bearings were tested as supplied (with seals and factory fitted grease), with grease removed and replaced by 20 W oil, and with seals removed but original grease remaining. The cup and cone bearings were tested after careful setup to minimise friction, with both 20 W oil and with an automotive chasis grease.

Results

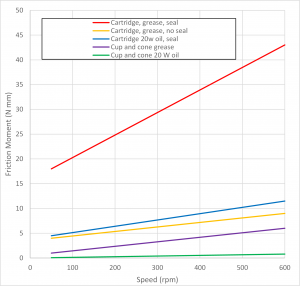

Surprisingly the results show that friction appears to be linearly dependent on rotational velocity but had no dependence on loading. The results also showed that sealed cartridge bearings had several times more friction when lubricated with grease than with oil. This was also true for cup and cone bearings. The effect of removing the seals from the sealed bearings was much more modest. Cup and cone bearings, lubricated with oil, had the lowest overall friction.

It is noted that the friction for bearing seals may be high as new bearings were used. Seals bed-in with use and their friction therefore reduces.

In the paper, charts are presented with straight lines fitted to the experimental data. The coefficients of these lines are not given although they would be the most useful way to present the findings. It would then be possible to represent the resulting resistance force as a function of these coefficients, the wheel radius and the velocity of the bicycle.

FWB = CWB0 / r + (CWB1 * 1000 / r2) * v

Where CWB0 and CWB1 are the coefficients, r is the wheel radius (mm) and v is the ground velocity (m/s). The factor of 1000 is required since the wheel radius is given in mm but the velocity is in m/s. Interpreting the data given in the charts in this paper, the coefficients will take the following values:

| Bearing type | CWB0 | CWB1 |

| Cartridge, grease, seal | 15.7 | 0.434 |

| Cartridge, grease, no seal | 3.5 | 0.087 |

| Cartridge 20w oil, seal | 3.9 | 0.122 |

| Cup and cone grease | 0.5 | 0.087 |

| Cup and cone 20 W oil | 0.0 | 0.013 |

Reference:

Title: Frictional resistance in bicycle wheel bearings, Cycling Science

Authors: K Danh, L Mai, J Poland, C Jenkins

In: Cycling Science, 1991, Vol.3(3-4), p.28-32

A great article, I wonder why they are used particularly in racing where every bit of of friction is important is a cup and spindle difficult to set up. The article sealed bearings wear in with use, how many miles does that take?

Good questions John. A cup and cone bearing is perhaps not convenient for the casual user but is certainly not too difficult to correctly set up for a professional mechanic. This is why racing group sets still use cup and cone bearings.